Mid-Sized Coaters for Production and Large-Wafer R&D Applications

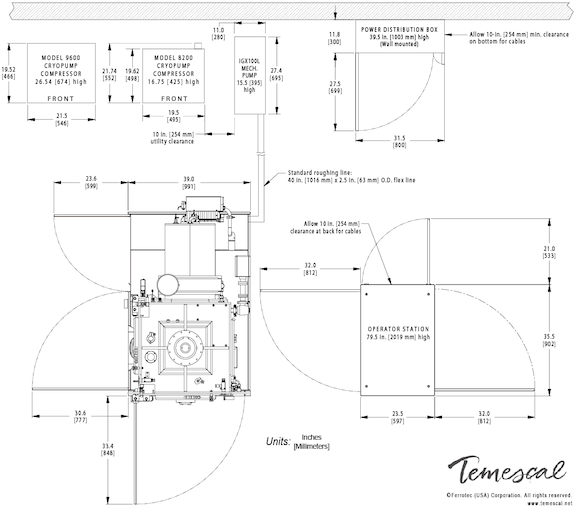

The Temscal FC-2800 and BCD-2800 are clean room-compatible coaters that offer high-throughput efficiency and lift-off capability at a source-to-substrate distance of either 34″ (866mm) or 42″ (1076mm). Both systems can be configured for either freestanding or through-the-wall clean room installation, and both support numerous combinations of deposition sources plus a variety of substrate fixtures and feeding, heating, and cleaning options.

Convenient Maintenance

The offset pumping port, the hinged door panels, and the swingout source tray are high-value maintenance features in Temescal systems. The offset pumping design reduces unscheduled downtime by minimizing the possibility of debris entering the pumping module. The hinged door panels open to the pumping system and the vacuum chamber. The electric hoist and the swing-out source tray facilitate access for evaporant reloading, cleaning, and maintenance. Access to the water manifold, the bellows-sealed high-vacuum valve, and other pumping system components is also simple and direct.

Key features:

- Non-load-locked BCD-2800 and load-locked FC-2800

- Product chamber dimensions: 28″ x 28″ x 28″

- Standard source-to-substrate distance: 34″

- S-S distance with optional source well extension collar: 42″

- Source tray supports multiple electron beam and resistance sources

- 3 cm or 5 cm ion source available in product chamber

- Product and source chamber cryopumps

System

- Production: 100mm

- Product Chamber Type: box

- Load Lock to isolate Product Chamber

- Cryopump water L/sec: 21,500

- Pump down time: 1E-06 < 20mins

- E-gun (max pkg): 4x25cc PopTop + 1 fixed pocket

- E-gun Power Supply: 6 or 12 kW

- Ion gun: MKII filament

- Max wafer count: Lift off 25x100mm, 12x150mm

- Source to Substrate: std 34″

- Source to Substrate: ext 42″

System Control

- Temescal Control System (TCS), with Auto, Manual modes plus process datalogging

- Security code-based access for multiple classes of users

- TCS-based process variable monitoring (PVM), allowing user to set tolerance alarms for critical process variables

- 17″ high resolution color touch screen interface

E-Beam

- Temescal 4- or 6-pocket Standard or PopTop turret source

- Temescal model CV-6SLX or CV-12SLX e-beam power supply (Simba option available)

- TemEBeam Contoller: Sweep, Index, Gun & HV

Substrate

- HULA: High Uniformity Lift-off Assembly

- Lift-off dome or dome frame with segments

- Step coverage High Speed Planetary

- Flip tooling: allows for two sided or edge coating

- VAP: Variable Angle Planetary

Vacuum Pumping & Control

- Market leading dry roughing pump >60 cfm (102 m3/h)

- CTI On-Board Cryopumps

- Cryopump temperature monitoring

- Active Inverted Magnetron gauges and Pirani controllers, monitored and controlled by the TCS

Product Chamber

- Dimensions in inches: 283

- Product chamber cryopump: CT-400, 17,500 L/Sec

- Water cooled product chamber walls

- Two sets of product chamber evaporation shields

- Wide-angle viewport on front of system

- One fixed uniformity mask

- Spare port(s) for RGA or alternate access

- Left-side door for service access

Source Chamber

- Source-isolation valve allows product chamber access while source chamber remains under vacuum

- Source chamber cryopump: CT-8, 4,000 L/Sec

- Source Tray Dimensions in inches 20

- Drop-down, swing-out source tray, accessible from either clean room or chase side of vacuum cubicle

- Wide-angle 4” viewport

- Removable stainless-steel source shields

Water & Air System

- Stainless steel manifold provides cooling water for source and product chamber components

- Separate product chamber circuit for cold and optional hot water

- TCS-controlled auto-blowdown for turret source

- PLC-controlled air manifold

System Wide

- 3 EMO switches

- Standard 19” wide electronics rack on casters

- Surfaces exposed to high vacuum are made of 304 SST

Temescal Control System

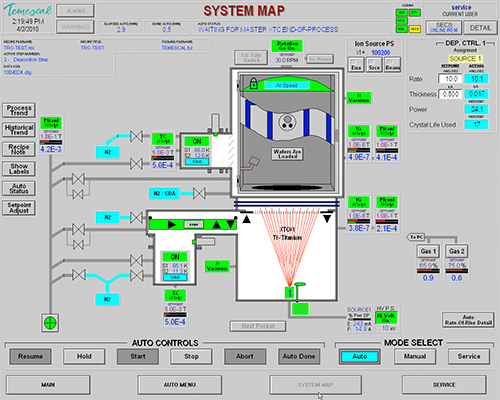

The Temescal Control System (TCS) provides fully integrated, recipe-driven process and vacuum control. Operating in any of three password-protected modes, the TCS also offers process variable monitoring, process and historical trend tracking, and process data logging.

TCS System Map During Deposition

The TCS Automatic Mode

Auto Mode operation provides fully automated execution of user-programmed recipes consisting of up to twenty process steps, as well as full abort diagnostics. The TCS Auto Mode also offers independent autopump and autovent operations, automated cryopump regeneration, and automated rate-of-rise testing.

Manual Mode Operation

The TCS Manual Mode enables the user to set process parameters, operate major components and subsystems individually with full interlock protection, and execute nonautomated single-film deposition processes.

Service Mode Operation

The TCS Service Mode provides noninterlocked low-level control over any of the system’s valves, pumps, motors, or power supplies.

Options

System control

- SECS/GEM interface to TCS

- Chamber temperature monitoring

- TCS-controlled auto-blowdown for turret source

- TCS simulator for off-line training and process development

- A second XTC/3 deposition controller to support codeposition

Electron beam source, power supply and sweep

- Upgrade to Temescal’s PopTop gun

- Up to three resistance sources

- 4-in. source well extension collar

- One additional fixed e-beam source

- One wire feeder per e-beam source on dual-source systems

- Dual wire feeders on single-source systems

- Power supply upgrade to 15-kW Temescal Simba2

- A second SS64 programmable beam sweep controller

Vacuum pumping and control

- Soft roughing and venting under TCS control

- Upgrade to a higher-capacity mechanical pump

Product chamber

- Substrate heaters

- One 3-cm ion source

- A residual gas analyzer

- A second CT-400 product chamber cryopump

- Product chamber and bell jar hot water circulation

- Process gas control for up to three gases

- High-speed planetaries for step coverage

Process

- Additional uniformity (shadow) masks

- Process development and film characterization

- Flip tooling for two-sided coating

Temescal FC-2800 Deposition System

For more information or to start a quote on a complete system

| Product | Capacity | Catalog # | Add product |

|---|---|---|---|

| Temescal FC-2800 deposition system | FC-2800 |

BCD/FC-2800 O-Ring & Shield Kits

| Product | Capacity | Catalog # | Add product |

|---|---|---|---|

| O-ring kit Select this to request O-ring kit information. |

0629-2355-0 | ||

| Shield Kit Select this product to request shield kit information. |

0627-3605-3 |

I Want to Learn More

To find out more about the UEFC-5700, start by submitting your completed registration form to Temescal.